Condition Monitoring (CM) is a core component of Asset Care Management, helping organizations optimize the health and performance of critical assets. CM involves continuously or periodically collecting data on the operating conditions of equipment, such as temperature, vibration, pressure, and other relevant parameters. This data is then analyzed to detect anomalies, predict failures, and schedule maintenance interventions before major breakdowns occur.

Key Elements of Condition Monitoring

Data Collection: Sensors and monitoring devices gather real-time or periodic data on critical parameters that reflect asset health.

Data Analysis and Diagnostics: Advanced analytics, sometimes including AI and machine learning, analyze collected data to identify deviations from normal operating conditions, which could indicate potential issues.

Predictive Maintenance: With insights from CM, companies can plan maintenance actions based on actual asset condition rather than fixed schedules, improving efficiency and reducing downtime.

Asset Performance Optimization: By understanding and managing the conditions that affect performance and lifespan, organizations can improve asset reliability, reduce costs, and extend asset life.

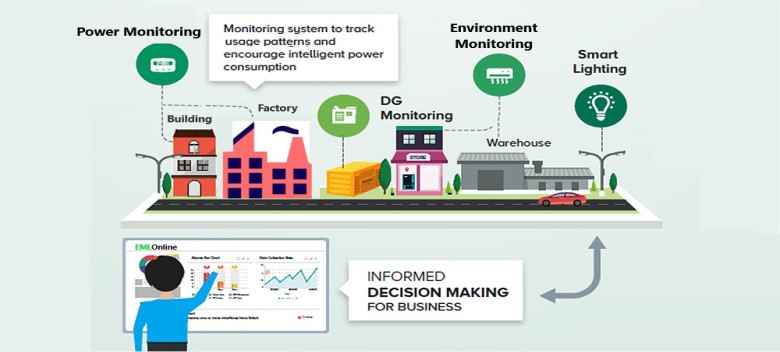

Integration with Asset Management Systems: CM data can integrate with broader asset management or enterprise systems to provide holistic insights, align maintenance activities with business priorities, and ensure optimal resource allocation.

Benefits of Condition Monitoring in Asset Care Management

Condition Monitoring is integral for industries relying on high-value equipment, such as manufacturing, utilities, oil and gas, and transportation, where asset health directly impacts productivity and profitability.